We put a lot of time and effort into designing and making these boots, and we know that’s what everyone says so let us show you exactly what decisions we’ve made with our factory in Portugal to ensure you get the best value for your money.

There are lot of information, as we want to be as transparent with you about everything in our process so you better understand what you’re investing in, in a pair of Sparrods and why you should make that investment. Without meeting you in person, this is the best we can do. To make it a lot more digestible, we’ve done our best to contextualize why we’ve made decisions and why that will matter to you as our customer. We also have detailed article on the different shoemaking methods which covers most of the techniques used for making shoes.

LAST

Before a boot or shoe design even gets considered the first step is to design and make a last. The last is simply a piece of wood or plastic that the leather of the boot is pulled over to form the actual shape of the boot or shoe.

Sparrods & Co - Lasts

It’s very important because it not only accounts for how the boot looks aesthetically, but how the boot fits. We’ve worked closely with a last maker to design a last that fits well for a range of different feet, providing ample room in the forefoot, but more importantly is a nicely fitted heel cup and a supportive arch.

GOODYEAR WELT

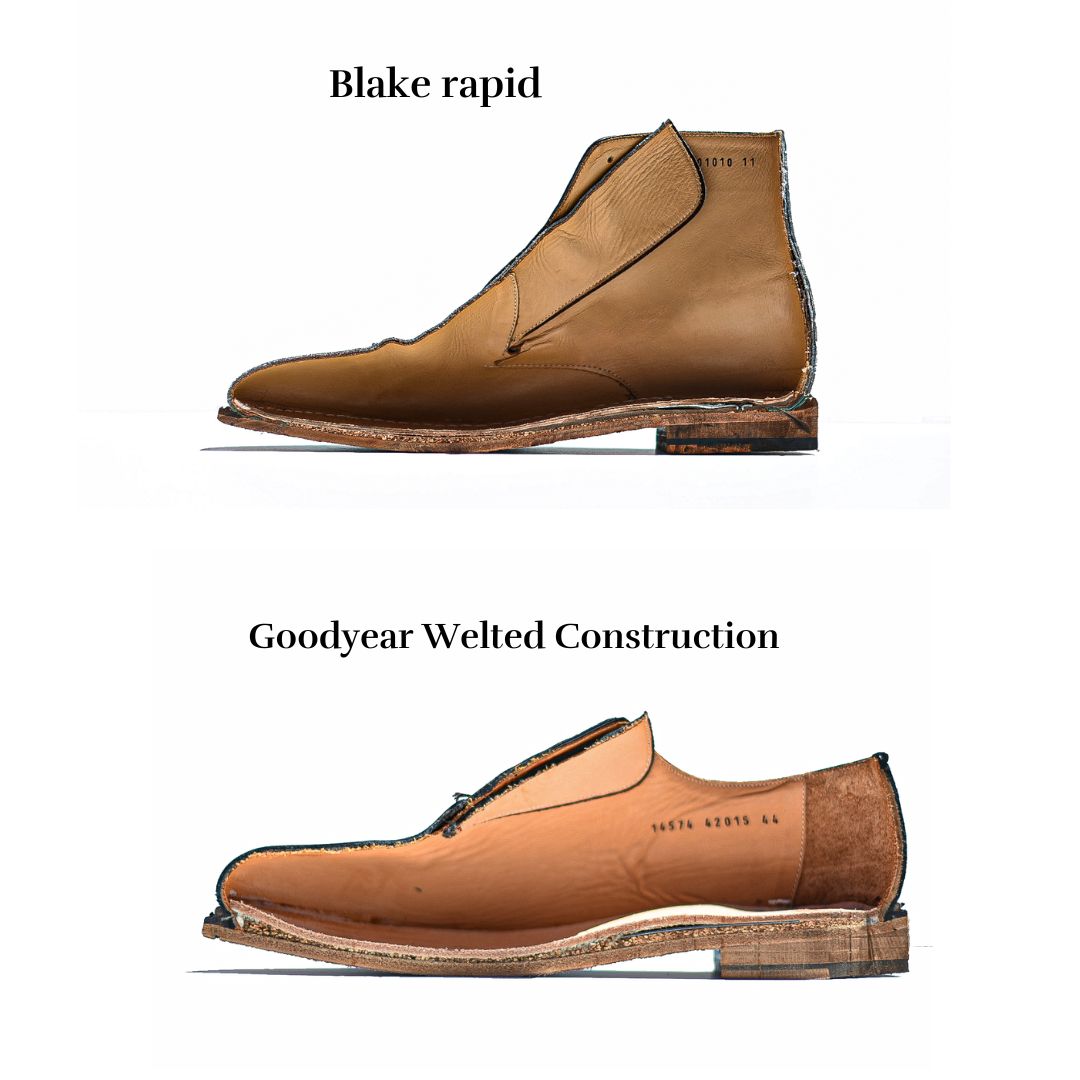

The goodyear welt method involves two levels of stitching. The first level is a welt stitch that attaches the welt to a piece of canvas rib called gemming which has been glued to the lower part of the shoe. This canvas rib leaves a void in the middle which is filled with the cork filling which we will discuss later, and a steel shank to ensure the stability under foot. Then when the shoe is ready to have a sole applied a rapid stitch is used between all the layers, combining the welt, midsole and outsole.

This method is preferred because it means they can be easily resoled as many times as you want. The entire gemming and lower portion of the shoe can be separated from the upper completely and replaced without destroying the shoe in anyway. Meaning your uppers can theoretically last forever. The only real downside of this method is that they are a little less flexible than other welt styles meaning they’re going to take a little longer to break in than Blake rapid stitched shoes and be a little less immediately comfortable.

As for our welt specifically, we’ve used a piece of full grain vegetable tan leather to make a 360-degree welt. This means when you replace your sole, a good cobbler can leave the welt where it is and just replace the sole, using the same holes and the last sole.

UPPER LEATHER

The upper leather makes up most of the boot, providing the color, texture and look of the boot. We use full grain calfskin leather. Full-grain calfskin is widely considered the pinnacle of leather quality for high-end boots and shoes, and for good reason. This premium material offers a unique combination of durability, comfort, and aesthetic appeal that sets it apart from other leather types.

Sparrods & Co - Full grain calf leather

First and foremost, full-grain calfskin retains the entire grain layer of the hide, including all of its natural characteristics and strength. This results in leather that is exceptionally durable and resistant to wear, ensuring that your footwear will stand the test of time. The dense fiber structure of calfskin also provides superior water resistance, helping to keep your feet dry in various conditions.

LINING

Leather lining is an important factor to consider when purchasing a quality pair of leather shoes. And as is usually the rule, more leather = better. By cutting our boots in half we’re showing you that not only do we say this, but we do also it. A high-quality lining is crucial for creating boots that are built to last. While synthetic linings may offer cost savings, they simply can't match the performance and longevity of soft calf leather. A full leather lining complements the exterior full-grain calfskin, creating a boot that's leather inside and out. This all-leather construction allows the boot to better conform to your foot shape over time, enhancing comfort and fit.

Leather lining

Leather linings are naturally moisture-wicking, helping to keep your feet dry and comfortable throughout the day. Unlike synthetic materials, which can break down or separate from the upper over time, leather linings age gracefully alongside the exterior leather. This cohesive aging process ensures that the internal structure of the boot remains intact, contributing to its overall durability and longevity. Additionally, leather linings are more resistant to odour-causing bacteria than synthetic alternatives.

COUNTER

The counter is a component that often goes unnoticed, but its importance can't be overstated. Located at the back of the boot, the counter provides crucial structure and support to the heel area. The leather counter plays a vital role in the overall performance and longevity of the boot. It helps to keep your heel securely in place, reducing slippage and improving overall stability. This is particularly important for preventing blisters and maintaining comfort during long periods of wear. Moreover, a strong counter contributes to the boot's ability to support your foot, which can help reduce fatigue.

Sparrods & Co | Leather Counter

Using leather instead of cheaper synthetic materials means our counters will hold up better over time. They won't break down or lose their shape, ensuring that the boot maintains its supportive structure throughout its lifespan. This is particularly important given that our boots are designed to last for years and potentially go through multiple resoles.

MIDSOLE

The mid sole is basically the part that goes below the insole and is a critical part of the boots construction to ensure that it moulds to your foot and becomes more comfortable over time. The midsole of our boots is a crucial component that significantly contributes to both comfort and durability. We start with a Goodyear welt construction, which includes a strip of material called gemming. This gemming is stitched to the insole and the upper, creating a strong foundation for the boot.

Sparrods & Co | Natural cork and steel shank at midsole

Between the welt and the insole, we use a natural cork filling. This cork layer is a key feature of high-quality boot construction. As you wear the boots, the natural cork gradually moulds to the shape of your foot, creating a custom footbed that offers personalized support and comfort. The cork also acts as a natural shock absorber, reducing fatigue during long periods of wear. On top of the cork, we add a layer of leather before the insole. This leather layer serves multiple purposes. First, it provides a stable surface for the cork to compress against, ensuring even distribution of pressure. Second, it adds another layer of natural material that contributes to the boot's breathability and moisture management.

It’s these components that make the boot comfortable in the mid to long term. It’s these midsole layers that you won’t (necessarily) replace between recrafting, keeping your boots comfortable, and more and more comfortable with age.

SHANK

The steel shank is a rigid component that sits between the insole and outsole, typically extending from the heel to the ball of the foot. Its primary function is to provide structure and support to the boot, and our choice of steel ensures it performs this task exceptionally well.

By using a steel shank, we're enhancing the overall stability of the boot. This added support helps distribute your weight evenly across the footbed, reducing strain on your feet and legs during long periods of wear. It's particularly beneficial when you're standing on uneven surfaces or climbing ladders, as it helps maintain the boot's shape and prevents uncomfortable flexing in the arch area.

INSOLE

The insole is where your foot directly connects with the boot, making it a critical element for comfort and fit. In designing our insole, we've struck a balance between immediate comfort and long-term performance, while also allowing for customization.

We begin with a foundation of high-quality leather, chosen for its durability, breathability, and ability to mould your foot over time. Recognizing that leather can be firm initially, we've added a thin layer of soft, spongy material on top (technically underneath). The spongy layer provides instant comfort, making our boots feel great right out of the box. It absorbs shock and minimizes pressure points, particularly beneficial during the initial break-in period. As you wear the boots, the leather underneath gradually conforms to your unique foot shape, creating a custom fit that improves with each wear.

We've made our insoles removable, serving multiple purposes. It allows for easy cleaning and airing out, helping maintain freshness and extend your boots' lifespan. It also offers the flexibility to replace the insole when needed, or to use custom orthotics if preferred.

STUDDED RUBBER SOLE

For all our Goodyear welted boots, we've chosen to use a studded rubber sole. This decision was made after careful consideration, working closely with our Portuguese factory to find the perfect balance of durability, comfort, and versatility. The studded rubber sole features a distinctive pattern of raised lugs that provide excellent traction on various surfaces. Whether you're navigating city streets or tackling slightly rougher terrain, these soles ensure you'll have a confident grip. But the benefits go beyond just traction. Rubber naturally outlasts leather in sole applications, and the studded design helps distribute your weight evenly, further extending the sole's lifespan.

Sparrods & Co | Studded Rubber Sole

Comfort was another key factor in our decision. Rubber absorbs shock better than traditional leather soles, reducing fatigue during long days on your feet. We've also struck a balance between ruggedness and refinement in the design. These soles are tough enough for daily wear. They're also naturally quieter than leather soles, a subtle but appreciated feature in many office environments.

LEATHER SOLE

We use vegetable tanned leather for the sole of our Goodyear welted oxford shoes, mens business shoes, leather loafers and mens leather boots. These soles are the most traditional, sleek and elegant sole compared to studded rubber sole.

Sparrods & Co | Vegetable tanned leather sole

Leather soles are flexible and can be resoled multiple times, extending the life of your shoes without causing any structural damage. They are incredibly durable and can last for many years with proper care. To expand the longevity of leather sole, we recommend the insert of topy for protection and slippage and prevents them from wearing out.

HEEL STACK

Our heel stack is built entirely from leather, a choice that speaks to our commitment to quality and durability. Layer upon layer of high-grade leather is carefully compressed and stacked to create a solid, sturdy heel. This full leather construction offers several advantages. It provides excellent shock absorption, helping to reduce fatigue during long days on your feet.

Sparrods & Co | Stacked Leather Heel with Rubber Injection

We've finished the heel with a thoughtful touch - a combination of leather and rubber injected on the edges. This hybrid approach gives you the best of both worlds. The leather maintains the classic, refined look that's essential for versatile footwear. Meanwhile, the injected rubber provides additional grip and durability where the heel meets the ground. This helps prevent premature wear and extends the life of your boots.

The result is a heel that not only looks great but performs exceptionally well. It's sturdy enough to support you through long days, and yet refined enough for more formal occasions. Like the rest of our leather boots, the heel is built to last. And when it eventually does wear down, it can be replaced as part of a full resole, allowing you to enjoy your favourite boots for years to come.

SUMMARY

Well, there you have it - a deep dive into the anatomy of our boots that would make even the most dedicated cobbler blush. We've taken you on a journey from the last to the leather, from the welt to the sole, and everywhere in between. If you've made it this far, congratulations! You now know more about boot construction than most people learn in a lifetime.

But here's the real kicker (pun intended): all this meticulous craftsmanship and carefully selected materials add up to more than just a sum of their parts. What you're really getting is a boot that's ready to become your loyal companion through thick and thin, rain or shine, from boardroom battles to weekend wanderings. So, lace up, step out, and let your Sparrods carry you forward. After all, life's too short for uncomfortable shoes, and the journey's always better in a pair of well-crafted boots.