The history of shoe making is a long and varied one, with different techniques and materials being used in different parts of the world and at different times. In general, however, it is believed that early shoes were made using simple techniques such as wrapping animal skins around the foot or using rawhide laces to hold them in place.

As time passed and human civilizations developed, more complex techniques for making shoes began to emerge. One of the earliest and most widely used techniques was the "turnshoe" method, in which the upper part of the shoe was sewn to the outsole and then turned inside out, with the seam hidden on the inside of the shoe. This method was used for many centuries and can still be found in some traditional shoe-making techniques today.

Over time, other methods of shoe construction developed, including Goodyear welt, stitched down, and Blake stitch, among others. These methods allowed for the production of shoes that were more durable, comfortable, and they continue to be used in modern shoemaking today. In recent years, advances in technology and materials have also led to the development of new methods of shoe construction, such as 3D printing and robotics, which are revolutionizing the way shoes are made.

Today, we are going to cover all the popular shoe making construction techniques, and discuss their pros, cons and some suggestions on what to look for when shopping for a quality pair of footwear.

HAND WELTED CONSTRUCTION

Hand welted shoe construction is a traditional method that involves hand stitching the upper, insole, and outsole of a shoe together. It is a time-consuming and labour-intensive process and requires skilled craftsmen to produces shoes of exceptional quality and durability. The shoemaker sews a strip of leather, called the welt, to the insole and the upper part of the shoe. The shoemaker uses a specialized tool, called a "welt knife," to cut the welt to the exact shape of the shoe.

Credit to: Cru Nonpareil | Hand-welted Lazyman Oxford Shoes

Hand welted shoes are known for their exceptional durability and longevity. The hand-stitching creates a tight bond between the upper, welt, and sole that is resistant to wear and tear.

Credit to: Cru Nonpareil | Bespoke Hand Welt Shoemaking

They are custom-made to fit the contours of the foot, which creates a comfortable and supportive fit. They allow for greater flexibility and movement in the shoe. They are considered works of art, with intricate stitching and fine materials. They are typically very expensive than those made with other methods.

GOODYEAR WELTED CONSTRUCTION

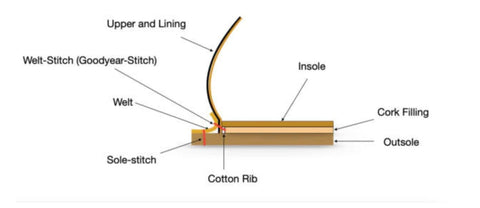

One of the first major developments in shoe construction that moved the industry beyond the simple techniques used in early human history was the development of the Goodyear welt. The Goodyear welt was invented in the mid-1800s by Charles Goodyear Jr., the son of the inventor of vulcanized rubber. It was named after his father, as it was initially used in the production of rubber-soled shoes. Goodyear welted, also known for its longevity, is a method of attaching the upper part of the shoe to the insole using a welt, which is a strip of leather or other material that is sewn around the edge of the insole.

Sparrods & Co | Kingston Goodyear Welted Oxford Wholecut

Credit to: Bespoke Unit | Goodyear welted method diagram.

To create a Goodyear welt dress shoes or boots, a shoemaker first cuts a strip of leather (the welt) to the desired width and shape. The welt is then sewn to the insole using a special machine, with the stitches passing through the insole, welt, and upper part of the shoe. The outsole is then attached to the welt using a series of stitches, which pass through the welt and outsole but do not penetrate the insole. This creates a "welt line" around the edge of the outsole, which is visible on the outside of the shoe. The welt adds an extra layer of protection against water seepage into the shoe.

Sparrods & Co | Goodyear Welted Lace Up Boots

The main pros of Goodyear welt method include its durability, comfort, and the ability to be resoled multiple times. The ability to be resoled multiple times extends the life of the shoe, making it more economical in the long run and makes them a great investment, especially if you take good care of them by rotating with other pair of shoes and regular polishing and conditioning.

Sparrods & Co | Natural Cork Infilling and Steel Shank

Goodyear welted shoes are generally more expensive to produce due to the labour-intensive process and specialized equipment required. They are heavier and sturdy due to the additional layers of material used in the construction process. Explore amazing collection of goodyear welted collections here.

Sparrods & Co | Kingston Goodyear Welted Oxford Wholecut | Black Calf

Sparrods & Co | Goodyear Welted Chelsea Boots | Espresso

Sparrods & Co | Kingsman Goodyear Welted Lace Up Boots | Black Calf

Sparrods & Co | Goodyear Welted Chelsea Boots | Black Calf

Sparrods & Co | Goodyear Welted Oxford Cap Toe | Black Calf

BLAKE RAPID

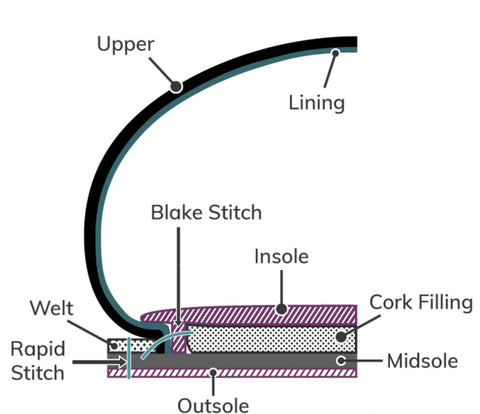

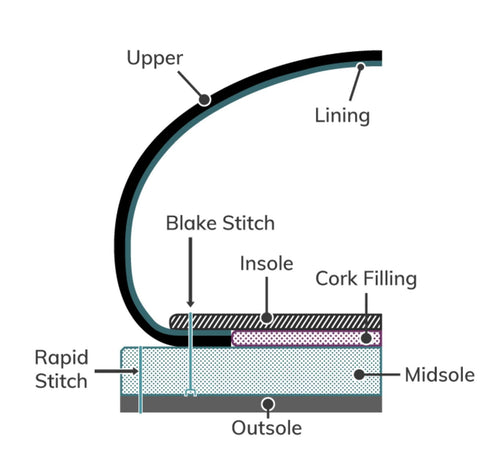

Blake rapid stitching uses a combination of Goodyear welted and blake stitched method of shoe making. It involves stitching the upper part of the shoe to the insole using a welt, which is a strip of leather or other material that is sewn around the edge of the insole. This method is like the Goodyear welt, but the stitches that attach the welt to the insole pass through both the insole and the outsole, creating a visible "welt line" around the edge of the outsole. The stitches provide a strong function for the upper, midsole and outsole.

Credit to: Bespoke Unit | Blake rapid stitched method diagram.

Blake rapid shoes are recrafted / resoled the same way as a goodyear welted shoe, by removing the sole stitch and attaching a new outsole which is then stitched in place with the same machine as for welted shoes. They can be resoled several times without impacting the structure and shape of the shoe which extends the shoe lifespan. They offer durability, and overall comfort.

Sparrods & Co | Blake Rapid Stitched Shoe Method

At Sparrods & Co, the midsole of all our blake rapid shoes is loaded with natural cork and steel shank which mould the shape of your feet and provide excellent arch support.

We use leather welt which is a strip of leather which connects the upper part of the shoe or boot including the vamp and quarters to the outsole by creating a stronger bond and sturdies which can withstand many years of wear. The welt helps prevent water from entering the shoe thereby making them ideal for all seasons wear irrespective of the climatic condition.

Sparrods & Co | Blake Rapid | Kingston Brown Oxford Wholecut Shoes

Sparrods & Co | Blake Rapid | Kingsman Burgundy Dress Boots

Sparrods & Co | Blake Rapid | Tan Brogues Boots

Sparrods & Co | Oslo Double Monk Strap Shoes | Espresso

BLAKE STITCH CONSTRUCTION

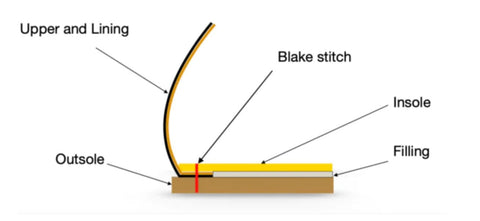

The Blake stitch is a method of shoe construction that involves attaching the upper part of the shoe to the insole using a single stitch that passes through the insole and outsole. This method was developed in the mid-1900s by Lyman Reed Blake, an inventor and shoemaker who was seeking to create a more efficient and streamlined way of making shoes. Blake developed the first machine for making shoes with the Blake stitch in 1856, and his company, L.R. Blake & Co., began producing shoes using this method in the late 1800s. The Blake stitch was initially used in the production of men's dress shoes, but it eventually became popular for a variety of other shoe types as well. Italians are well known for making blake stitched shoes.

Credit to: Saphir | Blake Stitched Construction

One of the main advantages of the Blake stitch is its sleekness, minimal appearance, efficiency, and simplicity. Unlike other methods of shoe construction, such as the Goodyear welt, the Blake stitch requires only a single stitch to attach the upper part of the shoe to the insole. This makes it efficient to produce shoes using this method, as it requires fewer steps. Shoes made with the Blake stitch are generally lighter in weight making them more comfortable to wear for extended periods of time and are recraftable with blake stitched machine.

Sparrods & Co | Blake Stitched Spectators with Brogues

One of the main drawbacks of the Blake stitch is less resistance to water. The single stitch used in this method does not offer the same level of durability compared the multiple stitches used in other methods like the Goodyear welt or Blake rapid stitched.

STITCHDOWN CONSTRUCTION

The Stitchdown method of shoe construction involves attaching the upper part of the shoe to the outsole using a series of stitches that pass through the insole, upper, and outsole. This method is similar to the Goodyear welt, but the stitches that attach the upper to the outsole are visible on the outside of the shoe, rather than being hidden under a welt. The Stitchdown method has a long history, dating back to ancient times when shoes were made entirely by hand. In the modern era, it has become more widely used in the production of work boots and other sturdy, functional footwear.

One of the main advantages of the Stitchdown method is that it allows for a great deal of customization and adjustment, as the stitches can be tightened or loosened as needed to achieve a comfortable fit. It is a durable method of construction, as the stitches provide a strong foundation for the upper and outsole. However, it is not as sleek or minimal in appearance as some other methods, such as the Blake stitch, and may not be as suitable for more formal or dressy footwear. Shoes made with this method are generally able to withstand the rigors of everyday wear.

NORWEGIAN WELTED CONSTRUCTION

Norwegian welt is a traditional method of shoe construction that has been used for centuries in Scandinavia. It is a type of stitchdown construction, in which the upper part of the shoe is stitched directly to the sole. This creates a strong, durable shoe that is ideal for rugged outdoor activities. The Norwegian welt involves stitching a strip of leather, called the welt, to the upper part of the shoe. The insole is then attached to the welt, and the outsole is stitched directly to the welt and upper part of the shoe.

Credit to: Saphir | Norwegian Welt Shoe Construction Method

The stitching is done in a distinctive pattern that creates a raised seam along the outside edge of the sole. Shoes made with the Norwegian welt method are known for their durability and strength. The stitching creates a tight bond between the upper, welt, and sole that is resistant to wear and tear. The raised seam along the outside edge of the sole helps to prevent water from seeping into the shoe. This makes Norwegian welt shoes an excellent choice for outdoor activities in wet conditions.

Shoes made with the Norwegian welt method tend to be more expensive than those made with other methods. The process is more labour-intensive and requires skilled craftsmen, which increases the cost of production. Norwegian welt shoes are heavier than those made with other methods, as the thick leather welt and additional layers of material add weight to the shoe. This may not be suitable for all consumers, particularly those who are looking for lightweight shoes.

MOCCASINS CONSTRUCTION

A moccasin is a type of shoe that is traditionally made of soft leather or suede and has a simple design that is easy to slip on and off. Moccasins were originally worn by Native American tribes and were designed to provide comfort and protection for the feet while walking on rough terrain. The construction of moccasins is relatively simple, with the upper part of the shoe consisting of a single piece of leather that is sewn together at the top of the foot. The sole is typically made of a single piece of leather or rubber that is shaped to fit the bottom of the foot, and may be decorated with beads, fringes, or other embellishments.

Sparrods & Co | Navy Moccasin

Moccasins are known for their comfortability and flexible design, which allows for a natural range of motion in the foot. The soft, supple leather conforms to the shape of the foot over time, providing a custom fit. Moccasins do not provide as much support as other types of shoes, such as athletic shoes or boots. This may not be suitable for individuals with foot conditions or those who require additional support. Moccasins are made from soft materials that do not provide as much protection as other types of shoes. They may not be suitable for individuals who need more protection from the elements or rough terrain.

SIDEWALL STITCH

Sidewall stitched construction is a method of shoe construction that is commonly used in the production of sneakers and athletic shoes. This construction method is known for its durability and ability to withstand the rigors of sports and other high-impact activities.

Sparrods & Co | Lasting of Explorer High Top Sneakers

Sidewall stitched shoes are durable and can withstand a great deal of wear and tear. The strong bond between the upper and the sole ensures that the shoe will hold up over time, even with frequent use. They are flexible, which makes them comfortable to wear and allows for a natural range of motion in the foot.

Sparrods & Co | Vin Low Top Sneakers | Espresso

Sparrods & Co | Explorer High Top Sneakers | Cognac

Sparrods & Co | Vin Low Top Sneakers | Suede Cognac

CEMENTED CONSTRUCTION

Cemented shoes, also known as cement construction, or cemented construction, refer to a method of shoe construction in which the upper part of the shoe is attached to the outsole using a strong adhesive, rather than being stitched or welted. This method is also known as "direct attach" construction.

Credit to: Saphir | Cemented Shoe Construction

The use of adhesives in the production of shoes has a long history, dating back to ancient times when natural materials such as tree sap and animal hide were used to attach the upper to the outsole. In the modern era, synthetic adhesives such as polyurethane and polyvinyl acetate (PVA) are commonly used in the production of cemented shoes.

Sparrods & Co | Cemented shoes

It is the cheapest and fastest method of shoe construction and does not require specialized equipment for shoe production. Cemented shoes are not durable, as the adhesive breaks down over time, fall apart very quickly and the shoes cannot be resoled. One of the main advantages of the cemented method is that it is a more economical method of shoe making and used by many brands compared to labour-intensive hand welted, goodyear welt or blake rapid construction which are more durable.

Sparrods & Co | Cemented Construction | Black Suede Chukka Boot

When choosing a pair of shoes, it is important to consider the specific needs and preferences of the wearer, as well as the intended purpose and occasion for the shoes. The Goodyear welt is suitable for a variety of types of shoes including dress shoes, oxfords, loafers, double monk strap shoes and boots. The Blake stitch and McKay welt are methods that produce shoes that are suitable for formal or dressy occasions, as well as casual or everyday wear. The stitchdown method is great for rugged workwear and functional footwear, including work boots and hiking boots.